ProfiMessage

A modular data acquisition system for applications requiring high-speed, precision data acquisition with galvanic isolation, intelligent data pre-processing and monitoring functions.

SKU

ProfiMessage

Category PC Data Logger

Manufacturer: Delphin Technology AG

Call for price

Description

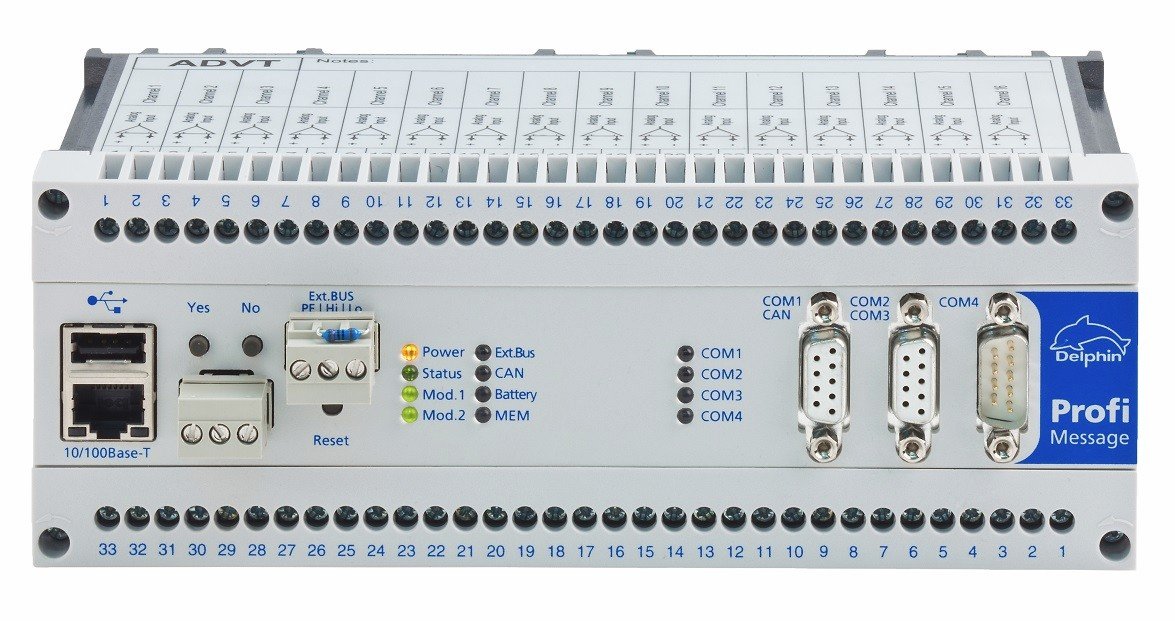

Compact Modular data acquisition and monitoring, ProfiMessage from Delphin Technology.

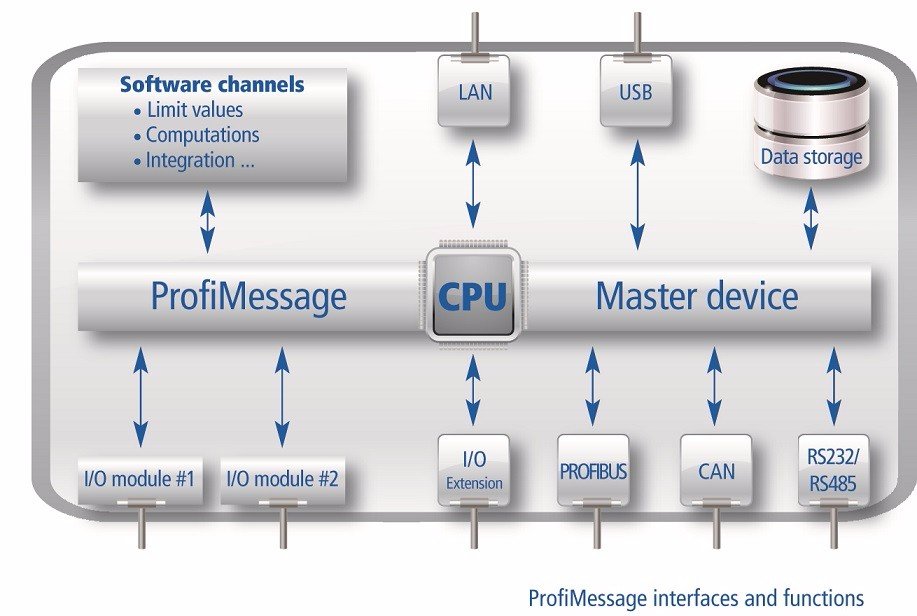

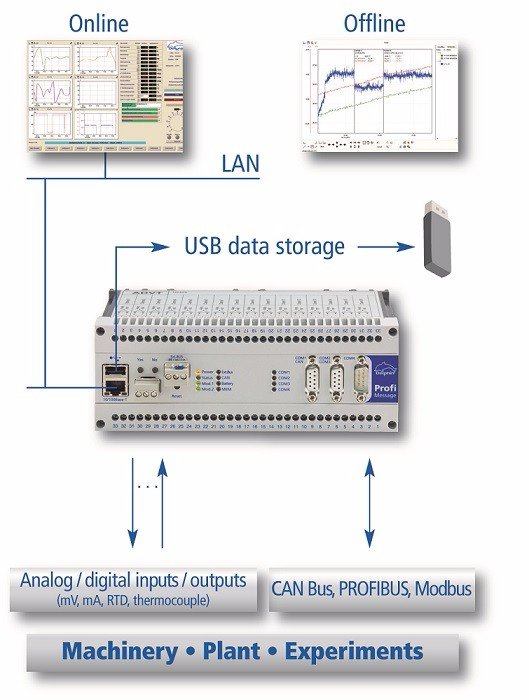

ProfiMessage is a modular system for data acquisition, monitoring and automation of machinery, plant and test stands. The system uses master and slave devices and a range of I/O modules to enable it to be adapted to any application.

The ProfiMessage device is designed for applications requiring high-speed, precision data acquisition, as well as galvanic isolation, intelligent data pre-processing and monitoring functions. It is ideally suited for applications such as monitoring of industrial processes, plant and clean rooms, as well as data acquisition and test stand automation.

ProfiMessage devices have a number of benefits. Firstly their universal connectivity. They are equipped with flexible I/O modules and a range of field bus interfaces. Connecting to PLC control systems for data exchange is easy and problem-free. Furthermore, measurement data is stored with extremely high time resolution. This makes it particularly well suited for fault data acquisition and diagnostics.

Another feature of ProfiMessage is that it is compact and can measure and store data as a stand-alone, independent system. An internal 16 GB memory is also able to record.

In addition, the data can also be accessed online via an Ethernet interface, either manually or automatically according to predefined time plans. At the press of a button on the USB port, the data can be transmitted to a USB memory stick and evaluated offline.

Product Features

- Secure and stand alone data acquisition

- Compact, modular design

- Monitoring and automation functions

- Combined process and vibration data

- Universal analogue inputs with high precision capability

- Galvanic isolation across channels

- Simple, intuitive configuration and operation

- Ethernet interface for online operation

- USB interface for data memory read out

- Two PROFIBUS interfaces (single or redundant, according to PNO 2.212 V1.2)

Applications

- Modular data acquisition and monitoring

- Process data acquisition and data pre-processing

- Fault data acquisition and damage diagnostics

- Acquisition, processing and recording of PLC and field bus signals

- Monitoring device for process and vibration signals

- Automation device for experiments and test stands

- Intelligent data logger with high capacity memory

- Remote monitoring device for plant and machinery, laboratory data acquisition and automation.

In conjunction with vibration measurement I/O modules, the ProfiMessage becomes a shaft and bearing vibration measurement device. Devices are then typically deployed in monitoring and analysis systems for condition monitoring. By attaching modems or router, users can use ProfiMessages as independent remote monitoring systems for plant, marine vessels, vehicles or similar decentralized machinery.

ProfiMessage devices are equipped with further functions in the form of software channels. Software channels enable functions such as threshold value monitoring, mathematical integration or online computations. They are extremely easy to configure. Users are then able to program their own monitoring or online analysis systems into the device without requiring any IT expertise. Delphin products stand out with this functionality. Users are then able to quickly and effectively deploy their ProfiMessage devices for their day to day requirements.

ProfiMessage Models

Two models are available.

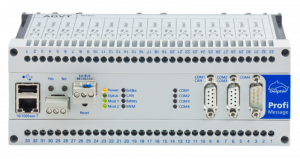

ProfiMessage – for industry

- Industrial-grade, compact design for cabinet installations

- Screw terminals

ProfiLab – for the laboratory

- Laboratory-proof, robust table-top design

- 4 mm laboratory or BNC connectors

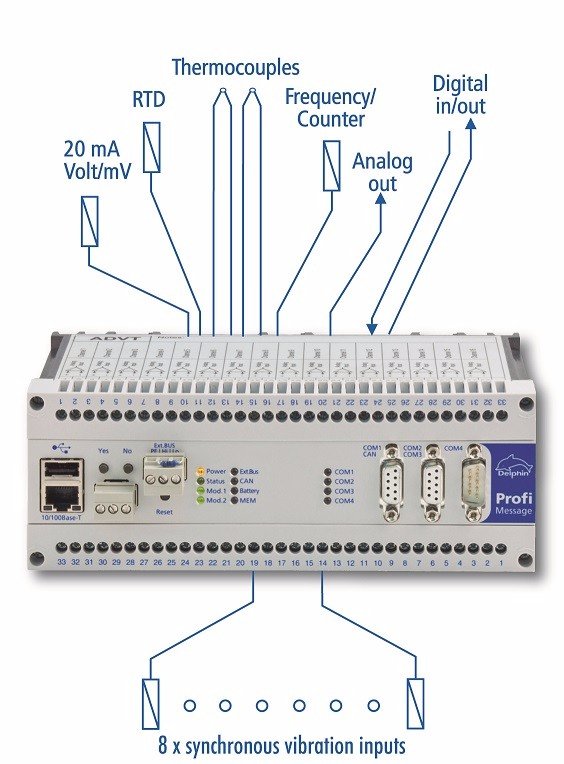

ProfiMessage Functions

Depending on the type of I/O module being used, each input can be configured separately to measure mV, mA, RTDs and thermocouples. Universal inputs enable the measurement of voltages, currents or temperatures making ProfiMessage extremely flexible to deploy. Additionally ProfiMessage is equipped with digital inputs, for functioning as status or frequency inputs, as well as digital / analogue outputs.

A major benefit of the ProfiMessage device is the differential, high-precision and galvanic isolation of its inputs and outputs. As a result, you benefit from isolation from channel to channel and from the power supply. Earth loops and non-isolated sensors therefore present no problems. This unique system architecture enables problem free non-isolated measurement.

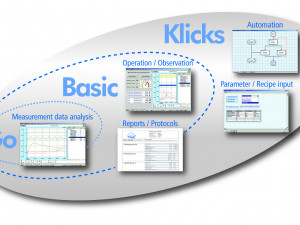

Simple and Intuitive Configuration

Configuration of ProfiMessage devices takes place using Configurator software that is included in delivery. The soft- ware gives a clear overview of channels, with operation being intuitive and similar to the Windows Explorer functioning. Double-clicking a channel opens a configuration dialog portraying all the channel’s properties.

The individual configuration files are stored in XML format within the ProfiMessage devices and can therefore be accessed and updated offline using an XML editor.

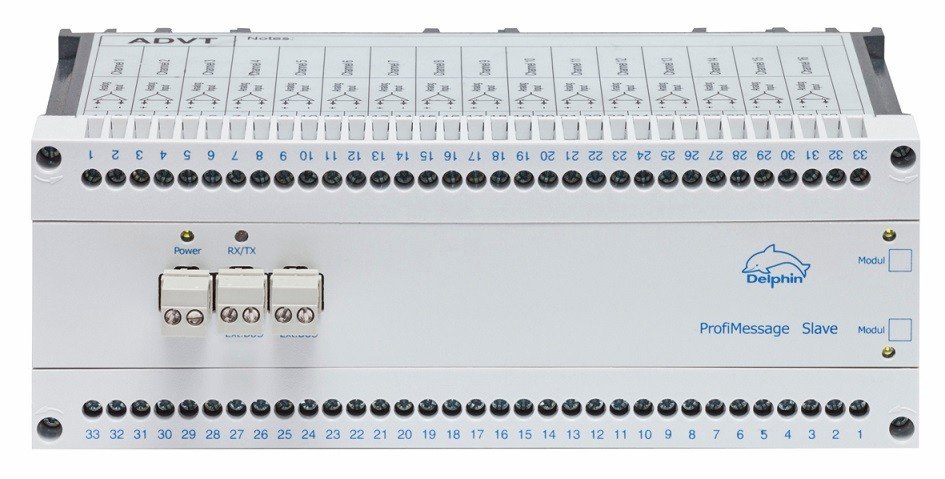

Flexible and extendible

ProfiMessage master/slave devices can be equipped with two modules. Up to 20 slaves, with identical housings, can be connected to a master device. Data exchange between devices takes place via a real-time expansion bus using robust two-wire technology. Slave devices can be decentrally installed and administered from a master device. Nine different I/O modules are available for ProfiMessage. A master or slave may contain either two identical or two different I/O modules. Master devices are also available without internal I/O modules for the exclusive processing of field bus signals – such devices can then function as PLC data loggers or deployed for process fault detection and diagnostic systems.

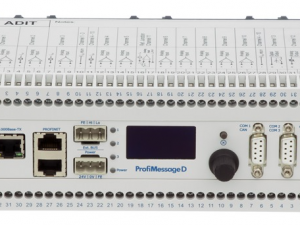

ProfiMessage Interfaces

ProfiMessage offers a range of field bus interfaces. A master device has two PROFIBUS DP slave interfaces (redundant according to PNO 2.212 V1.2), one Modbus TCP, one Modbus RTU, and one freely configurable CAN interface. The interfaces can also be used to connect any serial measurement devices and sensors via RS 232/485. An Ethernet high speed connection is for connecting ProfiMessage to a PC workstation or server.

PROFIBUS

ProfiMessage is equipped with two separate PROFIBUS DP slave interfaces. ProfiMessage integrates into PROFIBUS using GSD files. Virtually any analog or digital signal can be read or written from PROFIBUS. An option is available to switch the type of operation to redundant PNO 2.212 V1.2 PROFIBUS.

Modbus TCP / RTU

The LAN and RS485 interfaces can also transmit data via the Modbus TCP / RTU protocol. ProfiMessage supports both Modbus master or slave operation.

RS232 / RS485

The serial interfaces are able to function under different protocols. The protocols can be generated either by the user or by Delphin. ProfiMessage serial inter- faces are being used in climate chamber operation, for laboratory equipment, for power measuring hardware and GPS receivers.

CAN bus

The CAN bus interface can be programmed as required. Any identifier from a CAN bus can be read, scaled, pro- cessed and stored.

LAN / TCP

The LAN interface can be used to transmit all measurement data online, including software channels, at high speed via intranet or internet. Any networked PC can then access the ProfiMessage devices via this interface. There are also additional TCP services such as NTP, FTP, HTTP and SMTP etc. available. The device’s internal data memory can also be read out via LAN.

USB interface (Master)

The USB interface can be used to transmit data from the internal memory to USB memory stick.

Expansion bus

The expansion bus enables up to 20 slave devices to connected to the master device.

Extended Functions

Monitoring and automation tasks can be realised using ProfiMessage software channels. Software channels are pre-defined function modules that users can generate and configure per mouse click and then subsequently run within the device. All functions are performed autonomously by the powerful internal processor. This guarantees full operational security for the ProfiMessage device.

Module Type |

ADVT / AAST / ADIT |

ADGT |

AMDT / ADFT |

| Analog Inputs | |||

| Voltage / current measurement range | ±156mV to ±10V | ||

| Sensors | Thermocouples, RTD | - | |

| Potential isolation to system | 750VDC | ||

| Potential isolation to channels | 110V | 650V | 100V |

| Resolution | 24bit | 14bit | |

| Measurement accuracy | V / mA: 0.1% RTD100: 0.1K (except ADVT) RTD1000: 0.05K (except ADVT) Thermocouples: 0.1% EW |

0.1% - - - |

|

Analog outputs |

|||

| Resolution / potential isolation | 16bit | - | 12bit |

| Potential isolation | 750V | - | 100V |

| Output | 0/4 - 20mA | - | 0 - 10V |

| Max. load / min. load | 650ohm | - | 2.5Kohm |

Digital inputs |

|||

| Potential isolation | 2.5KV | ||

| Input measurement range | low: 0 - 1.5VDC @0 - 1.5mA / high: 3.5 - 90VDC @2mA | ||

Frequency / counter inputs |

|||

| Potential | 2.5KV | ||

| Measurement range | low: 0 - 1.5VDC @0 - 1.5mA / high: 3.5 - 90VDC @2mA | ||

| Measurement frequency | to 30KHz at TTL level | ||

Digital outputs |

|||

| Potential isolation | 2.5KV | ||

| Switching voltage | max. 50VDC @2.5A | ||

Data Storage |

|||

| Standard size / measurement values | Storage partitionable as required, standard 500MB Max. 32 million measurement values |

||

| Max. size / measurement values | 15.5GB / up to 1 billion measurement values (7 billion values for AMDT, ADFT) |

||

Interfaces |

|||

| Physical equipment COM1 / COM2 | RS485, 9-pole sub D-plug, DIN EN ISO 19245-1 | ||

| Physical equipment COM3 / COM4 | RS232, 9-pole sub D-plugs | ||

| Protocols COM1 / COM2 | PROFIBUS DPV1 Slave (both interfaces), incl. redundancy according to PNO 2.212 V1.2 | ||

| Protocols COM1 - COM4 | Modbus RTU master / slave, customer specific protocols | ||

| Ethernet | RJ45 (8-pole STP plug) 100base-TX Protocols: TCP/IP, HTTP, SMTP, NTP, Modbus TCP Client / Server |

||

| USB | USB 1.1 for configuration and data memory read out | ||

| CAN | 9-pole sub D-plug, Protocols: CAN Raw 50K - 1Mbaud rate | ||

Module bus |

|||

| Mechanical type | 3-pole Phoenix connector; internal bus to connect additional modules | ||

| Baud rate / length | 1 MBaud (adjustable) / up to 10m (1 MBaud) | ||

General technical information |

|||

| ProfiMessage Dimensions / weight | 200 x 73 x 118mm / 1Kg | ||

| ProfiMessage Fixing | Rail mounting DIN EN 60715 or screw fixing | ||

| ProfiMessage Signal connections | Detachable screw terminals, 33 terminals in 2 rows, lead protection, connecting cable max. 2.5mm2 | ||

| ProfiLab dimensions / weight | 226 x 145 x 180 / 1KG | ||

| ProfiLab signal connections | Up to 64 4mm lab plugs, gold-plated | ||

| Temperature range | -20 - 60°C | ||

| Power supply | 12 - 36VDC / 12-28VAC eff. / ±10%; at AMDT/ADFT min. 18VAC/DC | ||

| Power input | <10 Watt | ||

Request further information on this product below

You may also like…

Related products

-

DI-1100 4-Ch USB Data Acquisition Starter Kit

£70.00 ex VAT Add to basket -

DI-808 Web-based Voltage and Thermocouple Data Logger

£835.00 – £915.00 ex VAT Select options This product has multiple variants. The options may be chosen on the product page -

LoggitoLab Series

Call for price Read more -

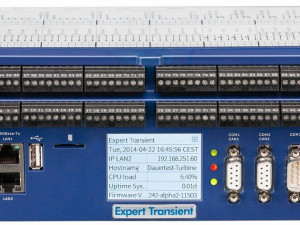

Expert Transient

Call for price Read more