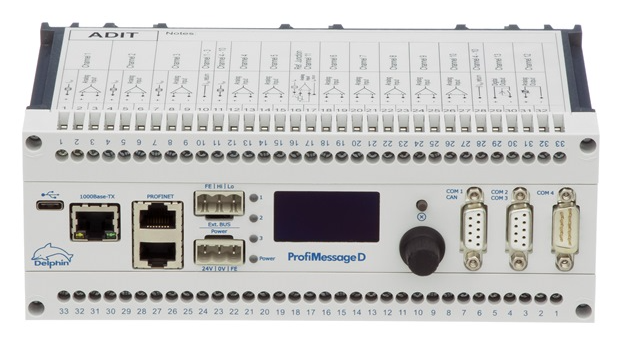

ProfiMessage D – Modular and Flexible Data Acquisition

A master/slave device concept and various I/O modules are used to tailor ProfiMessage D to your individual needs. The device inputs and outputs are differential, high precision and galvanically isolated from each other and from the supply voltage. This unique system architecture avoids disruptive ground loops and enables problem-free, non-floating measuring. Additionally, each input can be individually configured for measuring mV, mA, RTDs and thermocouples, according to the I/O module being used.

ProfiMessage D’s range of interfaces enables easy bidirectional data exchange with test stand components such as PLCs, smart meters and smart sensors. Interface setup and data exchange is also very simple.

Monitoring and automation tasks can be performed in the ProfiMessage D device via software channels, i.e. predefined function modules that are individually created, configured and processed by the user at a mouse click. For example, measurement data can undergo online processing using calculation channels. Limit value channels are used to monitor measurement data and, in the event of an alert, trigger alarms or send e-mails . You can therefore always be well informed about current events at your test stand.

Key Features of the ProfiMessage D device:

- Acquisition, signal pre-processing and autonomous storage of measurement data

- Monitoring functions with limit values and alarms

- Universal analogue inputs with high measuring precision

- High galvanic isolation between channels

- Simple, intuitive configuration and operation

- Ethernet and USB interfaces

- PROFINET, Modbus, CAN bus and serial interfaces

- Two PROFIBUS interfaces (single or ring redundant, according to PNO 2.212 V1.2)

- Optional WLAN interface

- Compact, modular design

- OPC UA client/server interface

Optional OPC UA HA server interface

Display for LAN configuration and measurement data

ProfiMessage D when used together with ProfiSignal software provide tailored solutions to setup and automate test stands: for product development as well as for end-of-line testing, whatever the type and number of measurement channels involved.

For more information, please contact us or see our Product Page.