Expert Vibro

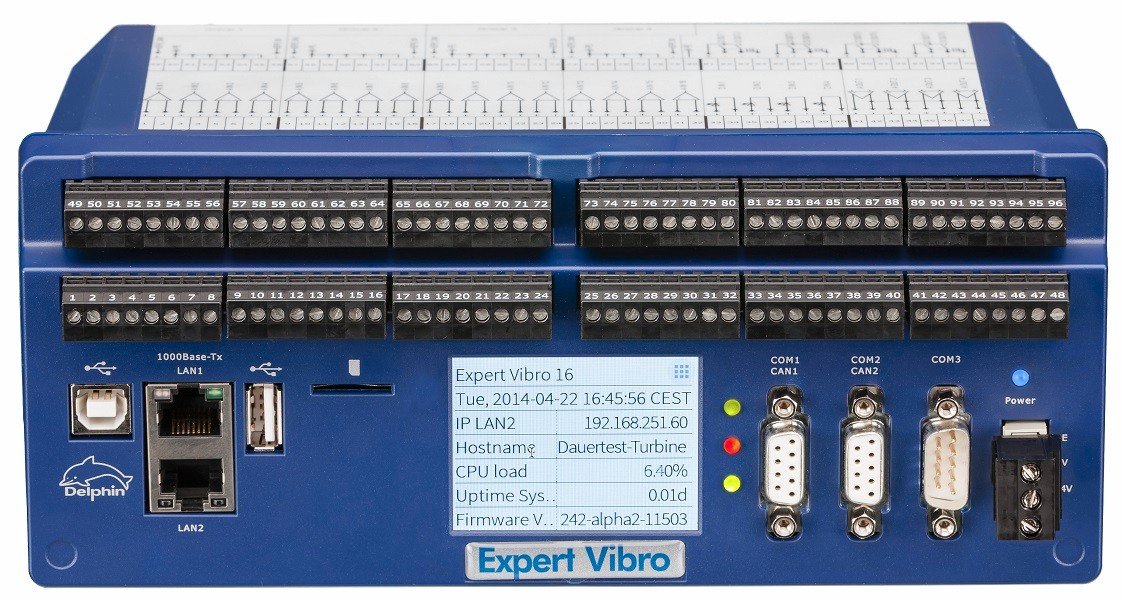

The Expert Vibro logger is designed specifically for acquiring transient signals and vibrations. The latest processor technology, based on powerful FPGAs, enables 4, 8, 12 or 16 synchronous channels to be processed at sampling rates to 50 kHz per channel while requiring minimal space. 24-Bit A/D converters ensure high precision.

SKU

Expert Vibro

Categories PC Data Logger, Standalone / Portable Loggers, Vibration Analyzer

Tags Battery and Fuel Cell Test Stands, Vibration Monitoring

Manufacturer: Delphin Technology AG

Call for price

Description

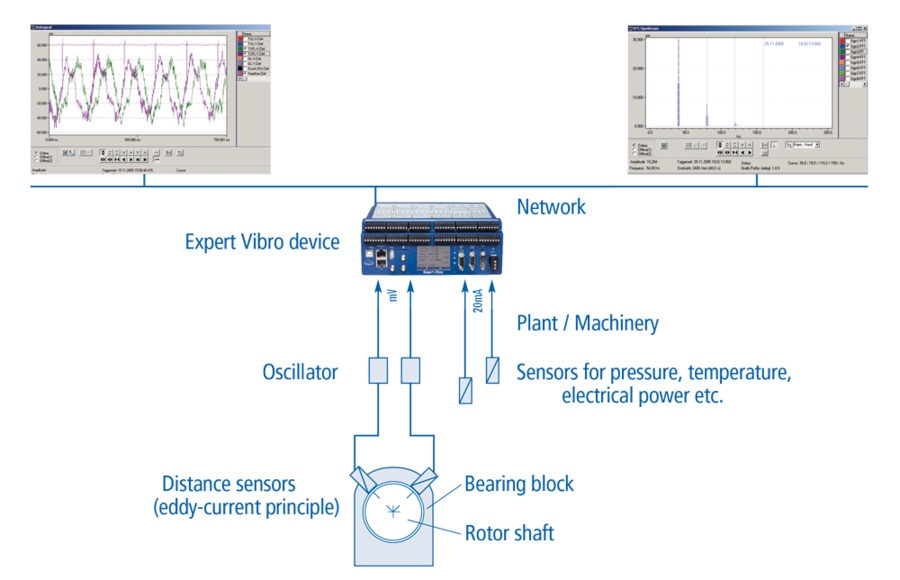

Vibration monitoring data logger – Compact, intelligent and fast

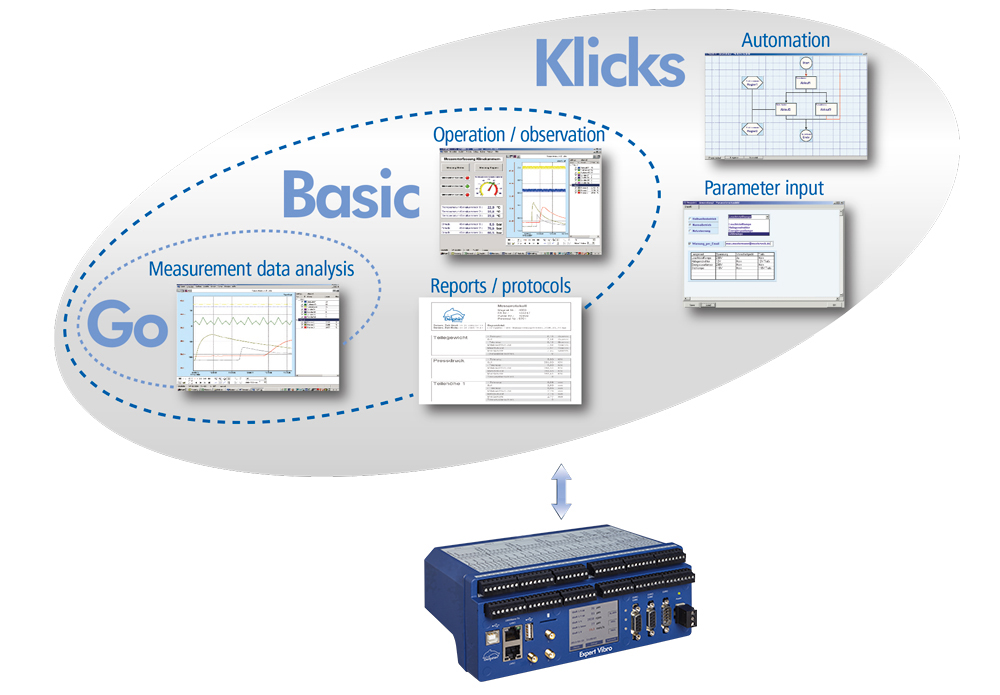

The Expert Vibro Vibration monitoring data logger is equipped with a high powered, dual core FPGA processor, based on ARM technology. Consequently, users have ample reserves of processing power when needed. Flexible switching is possible between measuring voltages, currents, IEPE or shaft vibration sensors. Another benefit is the integrated comparators and digital inputs, which result in flexible and speed-synchronised triggering. You can also monitor your measurement data online and digital outputs can be switched in milliseconds when limit values are exceeded. Additionally, you can record process data by using the relevant modules.

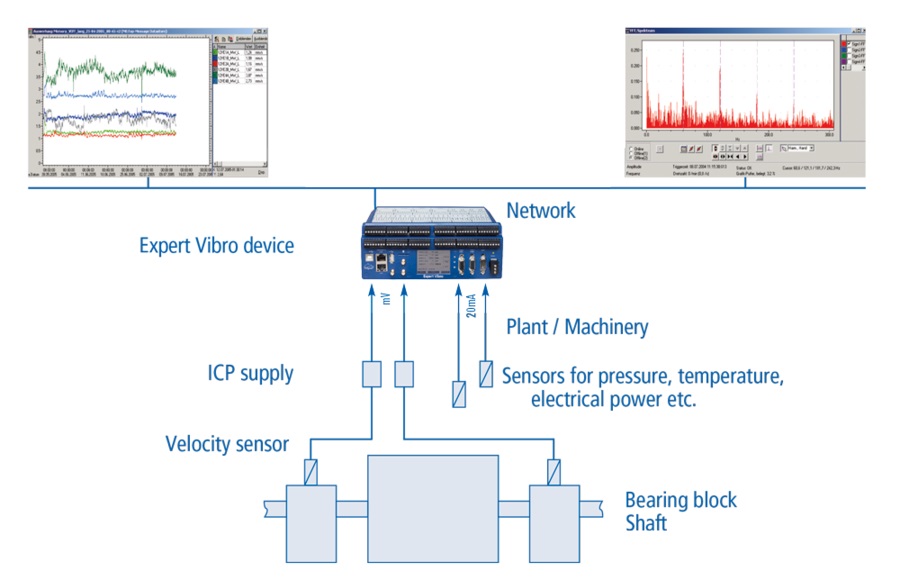

Vibrations deliver information on the condition of bearings, shafts and machinery and consequently have a major effect on quality levels in production processes. They should be continuously acquired, intelligently evaluated and condensed into meaningful data for monitoring. In critical situations, machinery needs to be shut down within milliseconds.

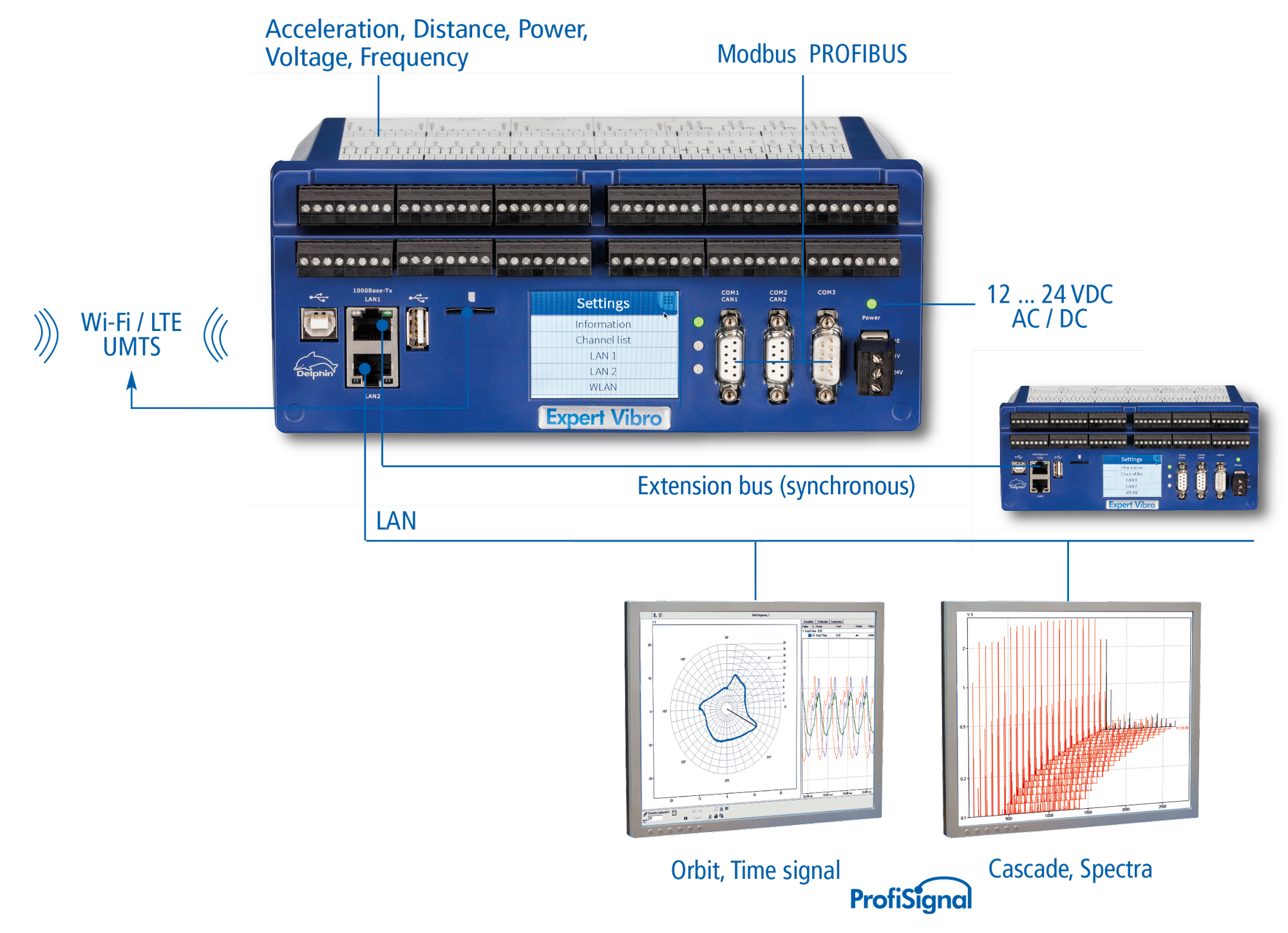

The Expert Vibro provides analysis and monitoring functions, and intelligent signal processing. You also benefit from an independent data storage capability and versatile fieldbus connections.

This modular system for signal processing comes with a range of pre-processing functions. Filters, such as high, low, or bandpass with rectifiers, integrators, differentiators or decimators can be selected to make up a pre-processing sequence. Moreover, multiple pre-processing sequences are able to run in parallel in order to evaluate an input signal. Significantly, this provides you with an especially high level of flexibility.

Another benefit is the precise analysis of non-periodic signals, such as in fault diagnostics. In continuous sampling mode, you can record even the smallest of irregularities. The Expert Vibro also measures, monitors and records fully independently. It is equipped with its own internal data storage capability making it especially reliable and secure.

Product Features

- 4, 8, 12 or 16 individually triggerable vibration inputs

- Calculation and monitoring of characteristic values

- Online computation of measurement data

- Integrated analysis functions for gear and roller bearing monitoring, air-gap etc.

- Spectrum – online – up to 12,800 lines (FFT)

- Integration functions (two-stage)

- 50 kHz sampling rate per channel

- 24-bit A/D converter

Sensor Connection

- Software switchable analogue inputs such as:

- Shaft vibration / distance sensors

- Acceleration sensors

- Vibration velocity sensors

- mV / mA signals (pressure etc.)

- Switchable IEPE power supply

- Integrated comparators for KeyPhasor® sensors

- Measuring range up to ± 25 V

- Pluggable screw terminals

Interfaces

- LAN, USB, WLAN (optional), LTE (optional)

- Serial interfaces RS232, RS485

- OPC UA, Modbus TCP/RTU

- PROFIBUS DP, CAN RAW

- Individual ASCII protocols

Data Storage

- 2 GB or 14 GB internal storage

- External storage media (USB, NAS)

- Triggered storage with pre and post histories

Vibration Monitoring Data Logger Applications

- Shaft vibration monitoring and analysis

- Machine and housing vibrations

- Combustion chamber vibration monitoring

- Gear box analysis

- Roller bearing monitoring and bearing damage diagnostics

- Mobile vibration measurement

- Air gab monitoring

Expert Vibro is suitable for many different types of application. It has universal sensor inputs which can be switched, via software, to the sensor type required. It is easy to connect IEPE accelerometer, speed or vibration sensors. You can also use any type of voltage or current output sensor e.g. fast pressure sensors for noise measurement / humming in combustion processes. You can configure each input individually. Additionally, velocity and shaft vibration measurement can be performed simultaneously.

Bearing Vibration Monitoring

Measurement, recording and monitoring of absolute bearing vibration on machines with roller-bearinged, rotating components, such as electric motors, pumps etc.

- Evaluation of vibration strength veff according to DIN ISO 10816

- FFT analysis within device / frequency band monitoring

- Bearing damage diagnostics using envelope curve frequency spectrum

- Monitoring of vibration levels

- Process and vibration measurement in a single device

- Modern recording memory in device

- Visualization and analysis in ProfiSignal using time signal diagrams trend, FFT-spectrum, FFT-cascade, orbit and polar diagrams

- Direct calculation of envelope spectrum

Shaft Vibration Monitoring

Various applications e.g. on turbines, compressors, boosters, large ventilators, etc. Measurement, recording and monitoring of the static and dynamic movement of journal-bearinged, rotating shafts (fixed bearing housing).

- Evaluation of peak to peak Spp and maximum deflection Smax according to VDI2059

- Sensor – wire break – monitoring

- Monitoring of static shaft position

- Monitoring of dynamic shaft vibration

- FFT analysis within device / frequency band monitoring

- Speed measurement and triggering via impulse from rotating shaft

- Process and vibration measurement within a single device

- Intelligent recording within device

- Visualization and analysis in ProfiSignal using time signal, trend, FFT spectrum, FFT cascade, and orbit diagrams

The Expert Vibro is also available as part of a customised measurement case. Click here for more details.

Inputs / Outputs |

|

Analogue inputs |

4, 8, 12 or 16 |

| Sampling rate, adjustable per channel | 20 Hz to 50 kHz |

| Usable signal range | DC to 20 kHz |

| Voltage range | ± 25 V |

| Current ranges | 0 to 20 mA / 4 to 20 mA / free |

| Signal conditioning, software switchable | None, AC coupling, IEPE |

| Resolution/Type ADC / input impedance | 24 bit Sigma-Delta / 4 MΩ |

| Dielectric withstand voltage | ± 100 VDC |

| Galvanic isolation: channel to channel / channel to system | ± 400 VDC |

| Measurement accuracy | 0.5 mV + 0.008 % from measurement value |

Digital inputs |

4 |

| Input signal | low: 0 to 1 V / high: 5 to 100 VDC@3.5 mA |

| Galvanic isolation: channel to other channel types / channel to system / PE | ± 400 VDC |

| Max. input frequency / min. pulse width | 1 MHz / 500 ns |

Analogue outputs |

4 |

| Resolution | 16 bit |

| Output ranges | 0 to 10 V / ± 10 V / 0 to 20 mA / 4 to 20 mA / ± 20 mA |

| Galvanic isolation: channel to other channel types / channel to system / PE | ± 400 VDC |

| Min. load / max. burden | 650 Ω |

Digital outputs |

8 |

| Max. switching voltage / current | 50 V / 2.5 A for 2 seconds, 250 mA continuous current |

| Galvanic isolation: channel to other channel types / channel to system / PE | ± 400 VDC |

| PWM basic frequency / duty cycle | 5 Hz to 10 kHz / 1:1000 |

Data storage |

|

| Internal / external | 2 to 14 GB (approximately 30 million measurements per GB) / USB, NFS, CIFS, (S)FTP |

Signal Conditioning Functions |

|

High-pass / low-pass / bandpass filter |

|

| Cut-off frequency / filter order / filter characteristic | 5 to 20 kHz / 4, 6, 8, 10 / Butterworth; Chebyshev, Bessel, Critical Damping |

Integrator / Differentiation |

|

| Single or double integrator / differentiator | |

FFT |

|

| Line number / window function / averaging | 100 to 12.800 lines (zero padding up to 32k points) / von-Hann, Hamming, Flat-Top, Tukey / 2 to 32 times |

| FFT types | Narrow band / wide band, envelope / demodulation, amplitude / phase spectra |

Characteristic values from time signal |

|

| Maximum / minimum value, peak-to-peak value, arithm. average, RMS, max. vect. sum, Air-Gap, Crest Factor | |

Characteristic values from frequency spectrum |

|

| Amplitude, frequency and phase of main oscillation and any harmonics, sum value, quadratic mean (in any frequency band), value remainder | |

| Amplitudes for various damage frequencies of rolling bearing, gear stage, planetary stage | |

Characteristic values on digital input |

|

| Frequency | 0.2 Hz to 1 MHz |

| Counter | 64 Bit, UP-Down counter, quadratur decoder |

Interfaces |

|

| Physical equipment COM 1 / COM 2 | RS485, 9-pole sub-D-socket, IEC 61158-2 |

| Physical equipment COM 3 | RS232, 9-pole sub-D-plugs |

| LAN | 1 x 1000Base-TX |

| WLAN / WWAN (optional) | 802.11b/g/n / GPRS, UMTS, LTE max. 100 Mbit/s |

| USB | Device 2.0 / host 2.0 / low / high / full |

| PROFIBUS | 2 x PROFIBUS DPV1 / Slave max. 12 Mbit, also redundant according to PNO 2.212 V1.2 |

| CAN / RS 232/485 | 2 x CAN 2.0 / Modbus RTU Master & Slave, SCPI, ASCII |

| TCP/IP | Modbus TCP Server & Client, OPC UA Server & Client |

General Technical Information |

|

| Dimensions / weight | W 217 mm x H 88 mm x D 128 mm / 750 g |

| Fixing | Rail mounting DIN EN 60715 or screw fixing |

| Signal connections | Plug-in screw terminals, 96 terminals in 2 rows, max. 1,5 mm² |

| Temperature range | -20 to 50 °C (Sufficient air circulation in the control cabinet must be ensured) |

| Humidity | max. 90 % relative humidity, non-condensing |

| Power supply | 12 to 24 VDC / ± 10% |

| Power input | max. 20 W |

Request further information on this product below

You may also like…

Related products

-

High Impedance Module for DAS1800

Call for price Read more -

DI-1100 4-Ch USB Data Acquisition Starter Kit

£70.00 ex VAT Add to basket -

DI-2108-P Programmable High-Speed USB DAQ System

£375.00 – £550.00 ex VAT Select options This product has multiple variants. The options may be chosen on the product page -

LogMessage

Call for price Read more