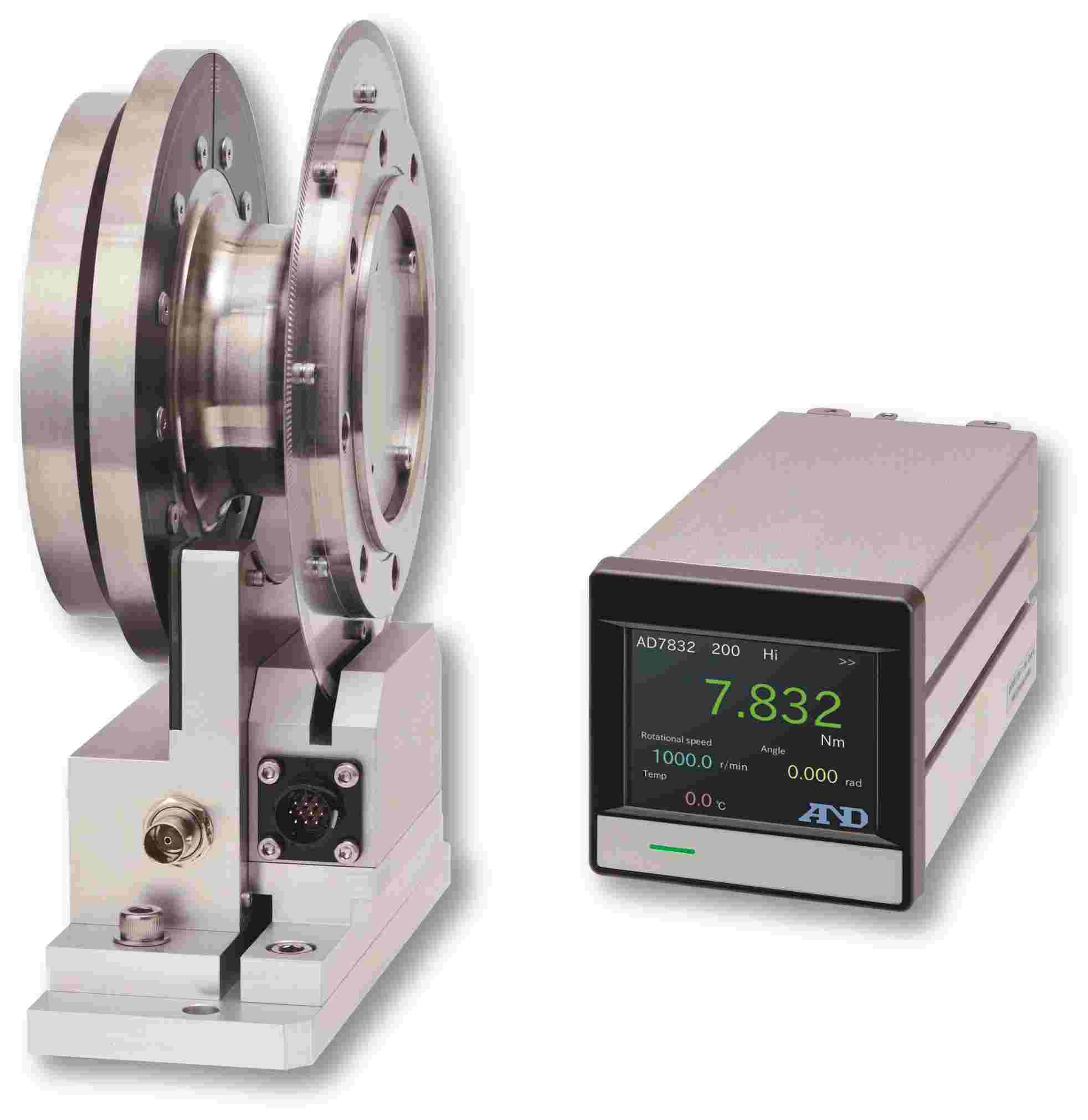

AD7832 Series Rotation Torque Sensor (RTS)

A range of torque sensors that can measure and display high-speed detailed phenomena

SKU

AD7832 Series

Category Load Cells

Manufacturer: A&D Company

Call for price

Description

The AD7832 series is a range of torque sensors with distributed force detection, created with A&D’s DSP technology and high-speed telemetry technology.

The series can measure and display high-speed detailed phenomena faster and at a higher resolution than conventional sensors. The Rotation Torque Sensor is designed for in shaft torque measurement e.g. as used for test beds for powertrain development.

Product Features

- Torque sensor featuring 1/3000 high resolution and robust construction

- Robust against vibration: Sensor can be installed to Engine output shaft without intermediate bearing.

- Real torque measurement using component force measurement

- Dual range with high accuracy (without degrading the total accuracy)

- Nominal torque: 200Nm – 5kNm

- Combined error: 0.03%

- Dual range: Combined error of 1/3000 is guaranteed at 1/5 of full scale

- Maximum rpm: 12,000 rpm (200 Nm) – 10,000 rpm (5 kNm)

Please contact us with your specification requirements.

Torque Sensor Specifications

| Model | AD7832 | |||||||||

| S200 | S200D1 | S500 | S500D1 | S1K | S1KD1 | S2K | S2KD1 | S5K | S5KD1 | |

| Performance Specifications | ||||||||||

| Rated Capacity (RC) | 200 Nm | 500 Nm | 1K Nm | 2K Nm | 5K Nm | |||||

| Full Scale (FS) *1 | 200 Nm | 200/40 Nm | 500 Nm | 500/100 Nm | 1K | 1K/200 Nm | 2K Nm | 2K/400 Nm | 5K Nm | 5K/1K Nm |

| Total Error Range *2 | 0.03 %FS | |||||||||

| Non-Linearity *3 | (0.02) %RC | |||||||||

| Hysterisis *3 | (0.02) %RC | |||||||||

| Repeatability *4 | 0.01 %RC | |||||||||

| Resolution *5 | 0.02 %RC | |||||||||

| Temperature Specifications | ||||||||||

| Temperature Effect at Zero point | 0.003 %RC/°C | |||||||||

| Temperature Effect on Sensitivity | 0.003 %Load/°C | |||||||||

| Temperature Range for Compensation | -10∼+60 °C | |||||||||

| Temperature Range for Operation | -20∼+80 °C | |||||||||

| Temperature Range for Preservation | -20∼+85 °C | |||||||||

| Rotation Specifications | ||||||||||

| Maximum rpm | 12000 r/min | 10000 r/min | ||||||||

| Continuous rpm | 12000 r/min | 10000 r/min | ||||||||

| Rotation Variation at Zero Point *6 | 0.05 %RC | |||||||||

| Machine Characteristics | ||||||||||

| Moment of Inertia (Kg•m²) | 4.0x10-3 | 5.0x10-3 | 6.0x10-3 | 9.0x10-3 | 14.0x10-3 | |||||

| Tortional Stiffness (kNm/rad) | 1.2x103 | 1.1x103 | 1.7x103 | 2.2x103 | 3.6x103 | |||||

| Tortional Resonance Frequency (kHz) | 7.9 | 7.9 | 8.3 | 7.8 | 8.0 | |||||

| Tortion Angle (rad) *7 | 0.2x10-3 | 0.4x10-3 | 0.6x10-3 | 0.9x10-3 | 1.4x10-3 | |||||

| Allowable Overload | 200 %RC | 150 %RC | ||||||||

| Maximum Overload | 500 %RC | 300 %RC | ||||||||

| Maximum Thrust Load | 5 kN | 10 kN | 20 kN | 30 kN | 50 kN | |||||

| Maximum Radial Load | 5 kN | 10 kN | 20 kN | 30 kN | 50 kN | |||||

| Maximum Bending Moment (kNm) | 0.2 | 0.5 | 1 | 2 | 5 | |||||

| Weight of Rotor (Kg) | 2.4 | 2.8 | 2.8 | 3.6 | 4.8 | |||||

*1 : Hi/Lo

*2 : Measured with static torque testing including non-linearity and hysteresis.

*3 : Reference number

*4 : Measured with static torque testing.

*5 : BW=100HZ

*6 : Value after revolution zero calibration

*7 : Torsion angle on rated torque value.

Sensor Signal Processor Specifications

| Model | AD7893-S |

| Exterior Dimensions | 97 (W) x 97 (H) x 208.2 (D) mm |

| Weight | 1.2Kg |

| Power Supply | Input: 90 - 240V 50 - 60Hz Output: DC12V 3A Supply from AC adaptor |

| Power Consumption | 20W (AC adaptor included) |

| Operation Temperature Range | 10 - 40°C |

| Interfaces | |

| Rotary Pulse Input | Line driver differential input (RS422/485 conformity) 3ch (A phase, B phase, Z phase) |

| CAN | Hi-speed CAN (differential signal I/F) CAN 2.0B 1ch |

| Analogue Output | Single end output 3ch (torque, revolution velocity and revolution angle) |

| Digital Input | Current drive input by photocoupler insulation (sink type) 2ch (range switch, zero point adjustment) |

| Digital Output | Open collector output by photocoupler insulation, 3ch (range switch, status and watchdog output) |

| Serial Communication | RS485 1 port |