Winlog

Winlog is a flexible, convenient and easy-to-use software package for the development of SCADA/HMI applications with a Web Server support.

SKU

Winlog Pro

Category Software

Manufacturer: Sielco Sistemi

Call for price

Description

Winlog SCADA Software from Sielco Sistemi.

Winlog is a flexible, convenient and easy-to-use software package for the development of multi-language SCADA/HMI applications. It is available in the basic version Winlog Pro and in the advanced version Winlog Evo, more suited for Industry 4.0 applications. Development tools include the libraries Symbol Factory (static graphic symbols) and Industrial Gadgets ActiveX (animated graphic objects).

Winlog supports most popular communication protocols (Siemens, Omron, Allen Bradley, Modbus RTU/TCP, KNX, BACnet, etc.) and provides OPC interfaces DA and UA (Client and Server). Furthermore it allows you to manage process recipes and to generate reports in both pdf and csv formats. It also provides an interface with external DB (MySQL, …) to record data (datalogger function) or directly access data through API. The “SecureBridge” function allows the remote user to directly operate on the PLC linked to the SCADA. Winlog allows you to set up distributed Client/Server architectures and create web applications accessible from smartphone or browser.

Key Features:

- Multi-language SCADA/HMI applications

- Thousands of symbols and animated objects

- Protocols Modbus, Siemens, Omron, KNX, etc.

- OPC Client interface and ODBC support

- History files exportable in CSV format

- Integrated programming language

- Distributed Client/Server architectures

- Applications with Web Server support

Product Features

Graphic Libraries

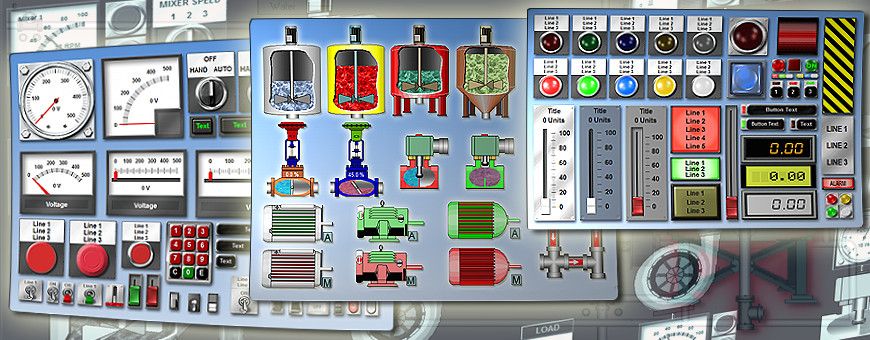

Development tools include Symbol Factory 2.5, the popular library of graphic symbols for industrial automation with over 5,000 manufacturing and industrial objects. These include graphics such as pumps, valves, motors, tanks, PLCs, piping, ISA symbols, etc; an integrated editor allows resizing and changing colour, scheme and orientation of objects (bitmap or metafile).

Development tools also include two libraries of animated graphic objects. The Industrial Gadgets ActiveX Basic Edition comes with animated objects both digital (e.g. buttons, switches, LEDs) and numeric (e.g. pointer indicators, potentiometers, led displays). The Industrial Gadgets ActiveX PRO Edition provides complex animated objects such as motors, pumps, valves, tanks, pipes.

Client/Server Architectures & Web Server Support

Distributed Client/Server architectures can be set up on Intranet/Internet networks. Several Winlog Pro applications installed on remote stations can communicate to each other via a TCP/IP protocol. Multi-master structures can be defined to allow both reading and writing between the various stations.

Distributed Client/Server architectures can be set up on Intranet/Internet networks. Several Winlog Pro applications installed on remote stations can communicate to each other via a TCP/IP protocol. Multi-master structures can be defined to allow both reading and writing between the various stations.

It is also possible to create supervisory applications with a Web Server support, hence accessible from any Internet Client with a simple browser. Two different solutions are provided to allow you to access the Server application. Firstly Web Client solution allows you to access the Server from fix devices supporting Java technology. Secondly the Smart Client solution provides access to the Server from mobile devices such as Smartphones and Tablets equipped with iOS or Android.

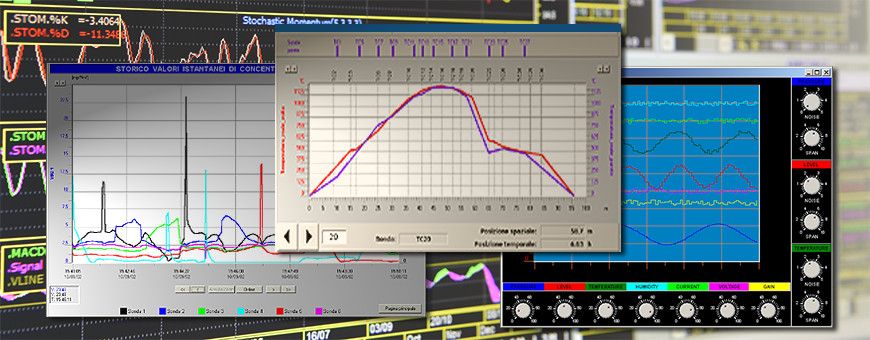

Graphical Trends

Trends give a graphical representation of monitored and recorded tags over time. It is possible to display simultaneously up to 10 trends relating to tags of different types, each with its own colour and scale. Various display options are available for trends (e.g. grid, line thickness, type of interpolation), backgrounds (colour, font) and positioning of the various elements (e.g. legend, buttons, cursor coordinates). It is possible to shift backwards and forwards the time axis, change scale, zoom the image or display the values of all tags plotted according to time coordinates.

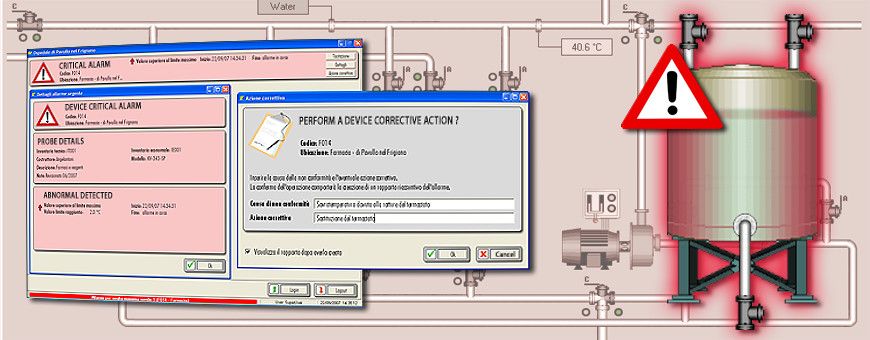

Events & Alarms

Events and alarms are types of gates activated or deactivated in relation to the value of an associated reference tag. A dedicated area of the screen allows an instantaneous display of alarms. Access to online information (active or not managed events) and historical (event beginning and end) is organized according to different freely assignable classes (e.g. priority, location, competence). In addition to date and time, any event can be associated with the value of multiple gates. This then provides a picture of the state of the system at the time of the onset of the event. Simple code routines allow sending of emails or SMS when a specified event occurs.

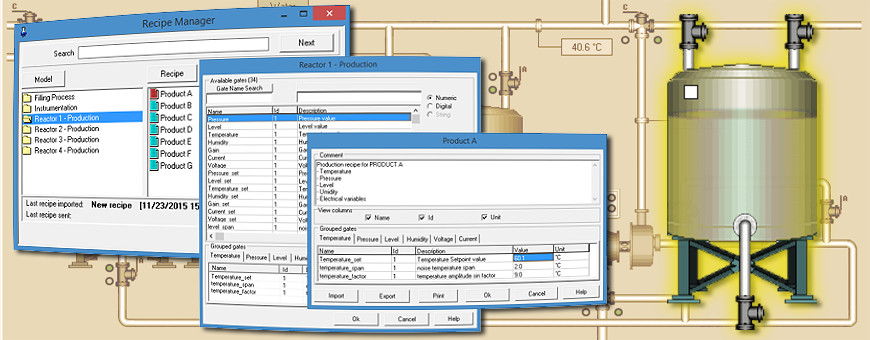

Recipes

Recipes are sets of characteristic values of a particular working process or a specific setting of the machine. It is possible to create several recipe models, each of which refers to a set of process variables (gates). Variables can be grouped together to allow application of joint actions. For every recipe model, it is then possible to create several recipes, each of which is made of a set of values assigned to the process variables defined in the recipe model. You can create, rename or delete both recipes and recipe models. In addition you can also create new recipes by importing values directly from the process. Furthermore you can send a recipe to the process manually (on operator request) or automatically (on software start-up), or following a trigger condition (e.g. in batch processes).

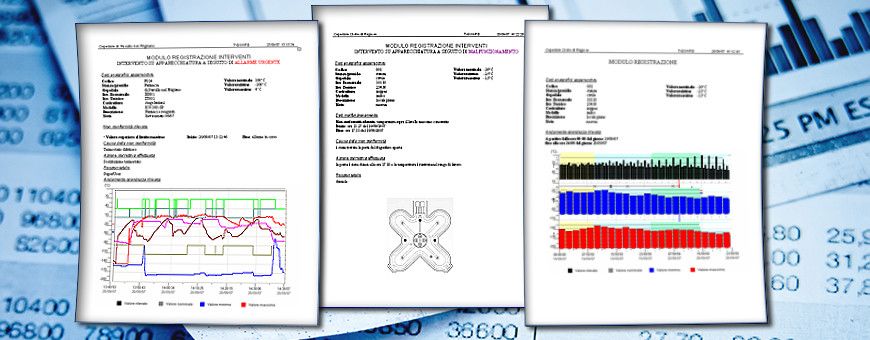

Reports

Reports contain a collection of historical information (production data, process quality, alarms) to be directly examined by production managers or imported and processed later by other Windows applications (e.g. Excel). In the first case reports are explanatory documents, drawn up in a predefine format, available on screen, printed or saved on disk as pdf files. In the second case, reports consist of files in a CSV format with data records registered at predefined time intervals. Reports can be either requested by the operator, or automatically generated on a cyclic basis (time interval, day of the week, etc.), or triggered by a specific condition (e.g. production end).

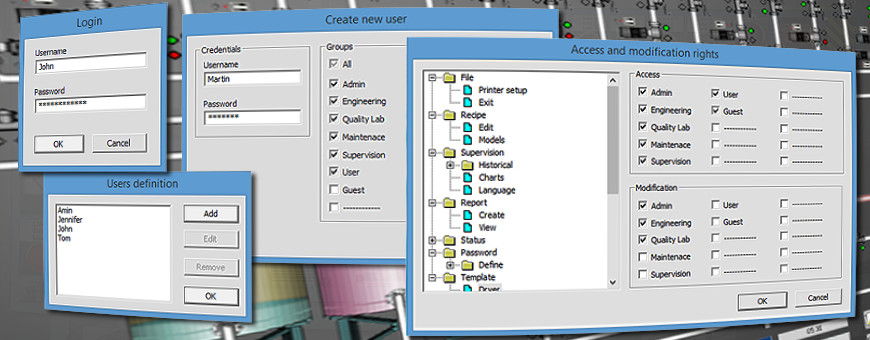

Security

Each menu item, template, tag, etc., can be protected assigning the groups authorized to access it and those who can modify it. A name, password, and membership of one or more groups can then be defined for an unlimited number of operators.

Every operator’s action that has produced a data modification is recorded in a history file by date, time, event description and operator’s name. This makes it possible to determine the causes of any irregularity in the operation of the system resulting from an operator action.

Development Tools

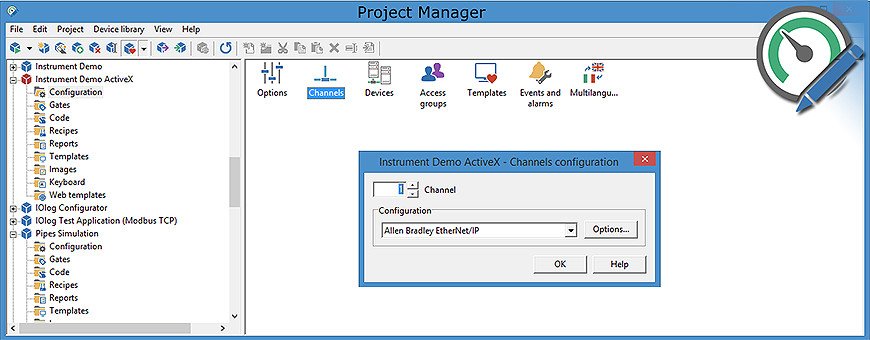

Project Manager is the integrated development environment that provides different tools (Gate Builder, Template Builder, Code Builder, Application Builder) for the easy and intuitive creation of any Winlog Pro application.

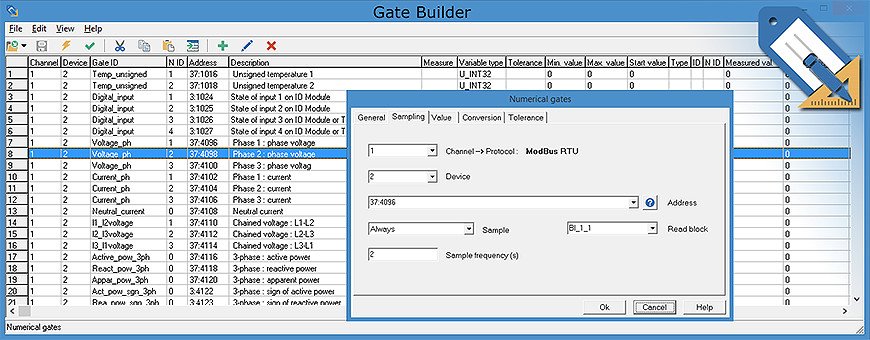

Gate Builder

Gate Builder is a tool for creating and managing the gates (tags) database. Different types of gates can be defined (numeric, digital, string, compound, event, alarm) and properties assigned (name, description, address, measurement unit, scale factor). Gates can be external (sampled from external devices such as PLCs, controllers, indicators, etc.) or internal. The sampling method can be configured for each gate or set of gates to obtain a satisfactory update frequency without using too much disk memory.

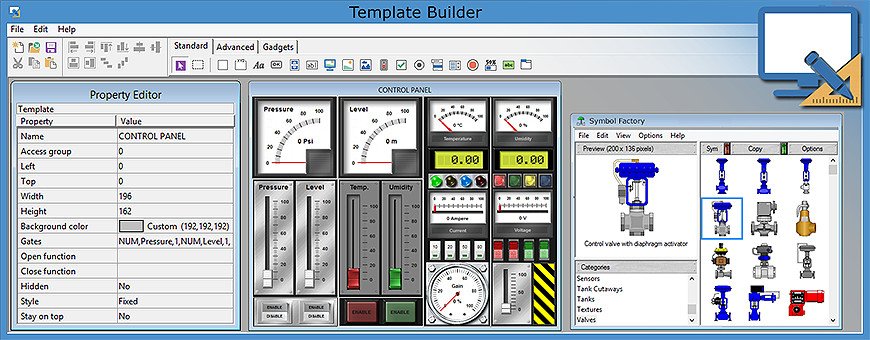

Template Builder

Template Builder is the tool for an easy and intuitive creation of templates and display pages; all you have to do to build a template is to arrange on the screen the objects (bitmaps, metafiles, text, values, status bars, LEDs and control icons) and to define their properties (dimensions, styles, associated tags, etc.).

Each object of the template can be assigned to a control that allows access only by the class of operators with a specific password level.

Template Builder includes Symbol Factory, the popular library with over 5000 symbols (pumps, valves, motors, tanks, PLCs, piping, ISA symbols), and Industrial Gadgets ActiveX, the graphical library with lots of animated objects: digital (buttons, switches, led), numeric (pointer indicators, potentiometers, led displays) and complex (motors, pumps, valves, tanks, pipes).

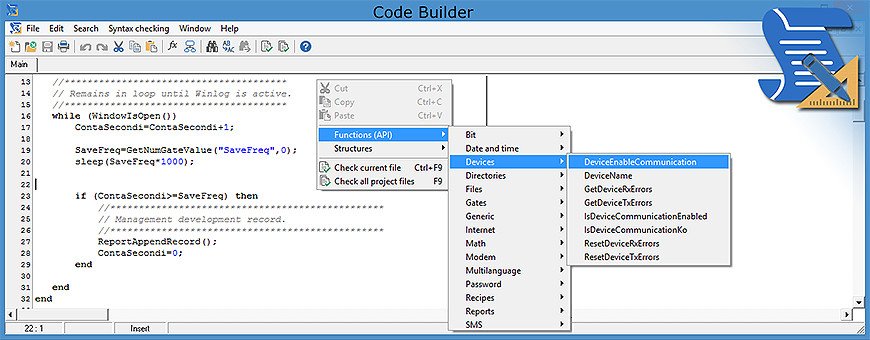

Code Builder

Code Builder is the integrated development environment that gives the possibility to enrich and customize the application; a simple C-like programming language allows the programmer to interact with all the components of Winlog Pro (tags, templates, recipes, reports, etc.), to define loops or “if-then-else” conditions, to create functions (Macro) that can be executed automatically or under operator control. The editor allows an easy recalling of all functions and language structures and provides a series of syntactic controls.

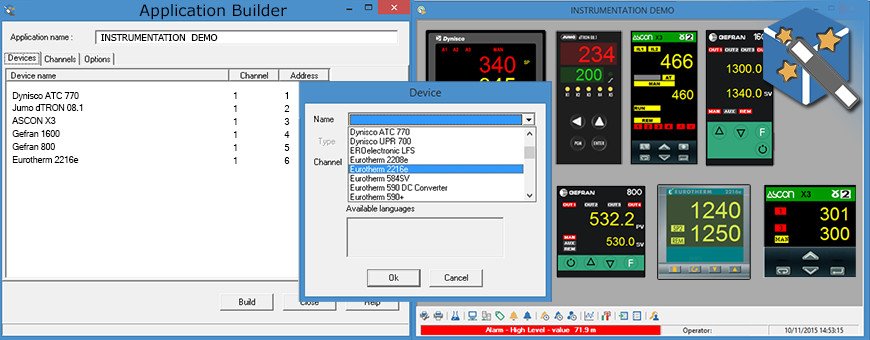

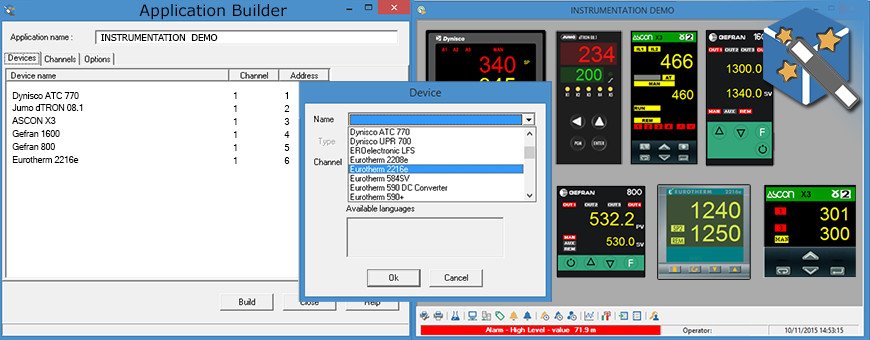

Application Builder

Application Builder is a powerful tool that allows the automatic creation of SCADA applications, resulting in a dramatic reduction in development timescales. You can create a software application by simply taking up from a library and putting together objects relating to various automation instruments such as PID controllers, indicators, I/O modules, etc.

In addition to tags and protocols, objects may include supervisory and configuration templates (front panel, trends, etc.) and a list of events and alarms with their management procedures. Objects can be built using the Multi-language option to allow the automatic creation of Multi-language applications.

Smart App Builder

Smart App Builder is the visual development tool for the quick creation of web applications (Smart Apps) that allow mobile devices (iOS, Android, Windows Phone) to interact with the Server application, in order to monitor and modify the variable values of the supervisory process (SCADA).

After defining the project variables, you can assign each of them a category and the display mode (item).

For each item, you can display and set data using a series of standard graphical controls including: Label, StatusBar, Bitmap UpDown, Edit Box, Slider, Combo Box, N-States Box, Switch.

The final structure of a Smart App consists of a menu composed of categories and their items and sub-items; browsing through the items is similar to that provided by all popular mobile devices.

Winlog Smart Client

Winlog Smart Client allows you to connect to a Winlog Server application through all popular mobile devices (iOS, Android, Windows Phone), in order to provide monitoring and control of remote plants and production processes. It takes advantage of the characteristics of JavaScript language to provide an encrypted TCP connection between remote Clients and Winlog Server. Thanks to an interface developed using the latest technologies (HTML5, JavaScript, CSS3), the user can access to plant information from a smartphone or tablet, by directly connecting to the Winlog Server application installed on the supervisory station. By entering the specific address (IP or hostname) into the address bar of a web browser (Internet Explorer, Firefox, Chrome, Safari…), you will see the home page from which to access the Server application.

Winlog web Client

Winlog Web Client allows you to connect to a Winlog Server application from any device equipped with a web browser. So you can remotely monitor and control plants and production processes, thus resulting in a dramatic reduction of maintenance costs. Winlog Web Client takes advantage of the features of JavaScript language to provide an encrypted TCP link between remote Internet Clients and the Winlog Server application. An interface developed with the latest technologies (HTML5, JavaScript, CSS3) allows the user to connect to the Winlog Server application installed on the supervision station, in order to access the information of the remote production plant. By entering the specific address (IP or hostname) into the address bar of a web browser (Internet Explorer, Firefox, Chrome, Safari…), the user will see the starting page from which to access supervision.

A special development tool allows you to turn a Winlog application into a Winlog Web Server application and to create a Winlog Web Client application that can access the Server and display or modify data through a subset of graphical objects including Frame, Group Box, Label, Button, UpDown, Edit Box, BkBitmap, Bitmap, Switch, Check Box, Radio Button, Combo Box, Led, Gauge, StatusBar, Chart, Historical Alarm/Event View. Multiple Clients can simultaneously connect to the same Server. From Winlog Server you can define which users are allowed to access (with username and password) via Web Client and assign to each of them the proper access level. The automatic data updating is ensured throughout the whole observation period. CSV and PDF reports generated by Winlog can be deployed in a special folder in the HTTP Server public area and then downloaded by remote browsers.

License Tools

The two versions have a similar structure and user interface, but differ in terms of performance and types of licenses.

The table below highlights the differences between the two versions in terms of performance.

| Features | Winlog Pro 3.0 | Winlog Evo 4.0 |

|---|---|---|

| Multi-Language support |  |

|

| Library of graphic symbols for Automation (Symbol Factory) | Ver. 2.5 | Ver. 3.0 |

| Library of animated objects for Industrial Automation |  |

|

| Support for vector graphics | WMF, EMF | SVG |

| Most popular RS485 communication protocols |  |

|

| Most popular Ethernet communication protocols |  |

|

| Application Builder (Smart Device Library) |  |

|

| OPC DA Client Driver |  |

|

| OPC UA Client Driver |  |

|

| OPC UA Server Driver |  |

|

| Ethernet Client/Server communication protocol |  |

|

| Historical and Online graphic trends |  |

|

| Historical and Online Alarms |  |

|

| Reports generated as pdf files |  |

|

| Reports generated as csv files |  |

|

| Reports on external DBMS (Datalogger function) |  |

|

| Special API to operate on external DBMS (MySQL, …) |  |

|

| Management of process recipes |  |

|

| Multi-Level access passwords |  |

|

| Access from smartphones (Smart Client) | Ver. 1 | Ver. 2 |

| Access from Internet Browser (Web Client) | JAVA | HTML5 |

| Quick Support for remote technical assistance |  |

|

| SecureBridge for remote access to the PLC |  |

|

| Watchdog realtime monitor |  |

|

| Runtime License with Editor Option |  |

|

| Development License with Runtime Option |  |

Winlog Pro licenses are supplied with a case containing a protection key for USB port. It is possible to supply an unlicensed protection key and later program it remotely with the required license. It is also possible to remotely upgrade a license to a license with a higher number of tags.

W-NET Development Licenses

Winlog Pro development licenses allow creation and running of both basic and web applications. Web applications have a web server support that allows access from smartphones or desktop PCs equipped with the Java Virtual Machine SE. Development licenses differ from each other only by the number of tags; development tools, communication protocols and other Winlog Pro functions are the same for all licenses. All development license include the libraries Symbol Factory (static graphic symbols) and Industrial Gadgets ActiveX (animated graphic objects).

- W-NET/SS-USB+: Development license up to 32 TAG

- W-NET/S-USB+: Development license up to 64 TAG

- W-NET/S1-USB+: Development license up to 128 TAG

- W-NET/I-USB+: Development license up to 256 TAG

- W-NET/I1-USB+: Development license up to 512 TAG

- W-NET/I2-USB+: Development license up to 1024 TAG

- W-NET/M-USB+: Development license up to 2048 TAG

- W-NET/X-USB+: Development license with unlimited TAG

W-R Runtime Licenses

Winlog Pro runtime licenses allow running of basic applications (without a web server support). Runtime licenses doesn’t allow you to modify the application by adding or removing sampled gates (tags).

- W-R/SS-USB: Runtime license up to 32 TAG

- W-R/S1-USB: Runtime license up to 128 TAG

- W-R/X-USB: Runtime license with unlimited tags

W-RW Web Runtime Licenses

Winlog Pro Web runtime licenses allow running of both simple and web applications. Web runtime licenses doesn’t allow you to modify the application by adding or removing sampled gates (tags).

- W-RW/SS-USB: Web runtime license up to 32 TAG

- W-RW/S1-USB: Web runtime license up to 128 TAG

- W-RW/X-USB: Web runtime license with unlimited tags

Winlog Evo licenses

Winlog Evo licenses are supplied with a case containing a protection key for USB port. It is possible to supply an unlicensed protection key and later program it remotely with the required license. It is also possible to remotely upgrade a license to a license with a higher number of tags.

Winlog Evo without a license

You can freely download the demo version of Winlog Evo, that allows you to develop and run SCADA application with no limit on the number of tags and 120 minutes of full operation. After two hours, communication with external devices stops and you have to restart the application. To run an application without any time limit, you must first validate it with a development license and then run it with a runtime license.

Winlog Evo Development license

The development license is required to validate the applications developed with Winlog Evo SCADA software. Only a validated application can run with a runtime license. The development license makes also available the graphic library Industrial Gadgets ActiveX, with a multitude of animated objects: digital (buttons, switches, lights), analog (pointer indicators, potentiometers, LED displays) and complex (motors, pumps, valves, tanks, pipes).

- W-EVO/DVX-USB: Development license with unlimited tags

Winlog Evo Runtime Licenses

Runtime licenses allow running of Winlog Evo applications previously validated with a W-EVO/DVX-USB development license; runtime licenses also allow you to modify the application (Editor option). Several runtime licenses are available, which differ only in the number of tags.

- W-EVO/RTA-USB: Runtime license up to 32 TAG

- W-EVO/RTB-USB: Runtime license up to 64 TAG

- W-EVO/RTC-USB: Runtime license up to 128 TAG

- W-EVO/RTD-USB: Runtime license up to 256 TAG

- W-EVO/RTE-USB: Runtime license up to 512 TAG

- W-EVO/RTF-USB: Runtime license up to 1024 TAG

- W-EVO/RTG-USB: Runtime license up to 2048 TAG

- W-EVO/RTH-USB: Runtime license up to 4096 TAG

- W-EVO/RTI-USB: Runtime license up to 8192 TAG

- W-EVO/RTX-USB: Runtime license with unlimited tags

Communication Drivers

Winlog supports communication with electronic instruments from most popular automation manufacturers, thanks to an extensive library of communication drivers and to the OPC Client interface.

OPC Interface

OPC (OLE for Process Control) is an industrial standard, created by main worldwide leading automation manufacturers, that allows data exchange between different software components without need of any special adjustment.

In addition to the OPC DA Client and OPC UA Client drivers, Winlog also includes the OPC UA Server driver to allow interfacing with the MES and ERP packages.

Driver Library

The following directory includes all available communication drivers sorted by manufacturer or by protocol; other drivers, not included in the present catalogue, can be supplied on request or developed under customer specification.

Manufacturer |

Device |

Protocol |

| ABB | Inverters series ACS |

|

| Acromag | Modules I/O series BusWorks 900EN |

|

| Modules I/O series BusWorks 900MB |

|

|

| Advantech | Modules I/O series ADAM 6000 |

|

| Allen Bradley | PLC series 3 |

|

| PLC series 5 |

|

|

| SLC500/MicroLogix |

|

|

| Aros | Inverter series Sirio |

|

| Ascon | Controllers A/C Station |

|

| Series delta2 |

|

|

| Series gamma2 |

|

|

| Series J2 |

|

|

| Series sigma2 |

|

|

| Automationdirect | PLC series CLICK |

|

| PLC series DirectLogic |

|

|

| PLC series Productivity 3000 |

|

|

| Ave | Ave ABDI: analog output receiver |

|

| Ave ABR: ON/OFF output receiver |

|

|

| AVE ABRT: roller shutters output receiver |

|

|

| Ave ABT: transmitter module |

|

|

| B&R Industrial Automation | Modules I/O series X2X Link |

|

| Bentel Security | Security system KYO320 |

|

| Bticino | Ticontrol devices |

|

| Contrex | Dosers series Dexxxx |

|

| Cooperativa Bilanciai | EV2001 |

|

| CR Magnetics | CRD5110 |

|

| CRD5150 |

|

|

| CRD5170 |

|

|

| Danfoss | Inverters series VLT |

|

| Dataforth | IsoLynx® SLX300 Data Acquisition System |

|

| Datexel | Modules I/O series DAT3000 |

|

| Digitek | Controllers Micropid |

|

| Doteco | Dosers |

|

| Dynisco | Pressure controller ATC770 |

|

| Pressure indicator UPR700 |

|

|

| Elettronica Santerno | Inverter series Etesian |

|

| Inverter series Sinus |

|

|

| Inverter series Sunway |

|

|

| EroElectronic | DIN-rail multiloop controller series RFS |

|

| Front panel instruments |

|

|

| Eurotherm | DIN-rail multiloop controller series 2500 |

|

| Front panel instruments |

|

|

| Inverters series 500 |

|

|

| Inverters series 600 |

|

|

| Fuji Electric | Front panel instruments |

|

| GE Fanuc Automation | PLC series VersaMax® Micro Plus |

|

| Gefran | DIN-rail multiloop controller series GEFLEX |

|

| Front panel instruments |

|

|

| Generic | BACnet devices |

|

| Cameo light |

|

|

| Cameo light |

|

|

| Clay Paky |

|

|

| Coemar |

|

|

| Generic dimmer |

|

|

| Generic DMX RGB controller |

|

|

| ROBE lighting |

|

|

| Honeywell | HC900 |

|

| UMC800 |

|

|

| Horner APG | PLC series NX |

|

| PLC series QX |

|

|

| PLC series XL |

|

|

| Idec Izumi | PLC series FA |

|

| Ime | Energy meters series Conto |

|

| Energy meters series Nemo |

|

|

| Janitza electronics | Energy meters series UMG |

|

| Jumo | Controllers series Dicon |

|

| Controllers series dTron |

|

|

| Modules I/O series mTron |

|

|

| Klockner Moeller | PLC series PS3 |

|

| PLC series PS4 |

|

|

| KNX | Any KNX/EIB device |

|

| Koyo | PLC series DirectLogic |

|

| M-Bus

|

Caleffi CONTECA® |

|

| Engelmann SENSOSTAR 2/2+ |

|

|

| IME Multifunction device with M-Bus IF96013 interface |

|

|

| Matsushita | PLC series FP |

|

| Mitsubishi | Inverters series FR |

|

| PLC series FX |

|

|

|

PLC series L |

|

|

| PLC series Q |

|

|

| Modicom | PLC series Momentum |

|

| PLC series Premium |

|

|

| PLC series Quantum |

|

|

| Moxa | Modules I/O series IoLogik |

|

| Omron | PLC series C-H |

|

| PLC series C-K |

|

|

| PLC series C1000H |

|

|

| PLC series C200 |

|

|

| PLC series C2000H |

|

|

| PLC series CJ |

|

|

| PLC series CPM1 |

|

|

| PLC series CQM1 |

|

|

| PLC series CS |

|

|

| PLC series CV |

|

|

| PLC series CVM1 |

|

|

| Panasonic | PLC series FP |

|

| Phoenix Contact | PLC series NanoLine (nLC50) |

|

| Red Lion | Front panel instruments |

|

| Rieter | Winders |

|

| Saia | PLC series PCD |

|

| Samson AG | PLC series TROVIS |

|

| Schneider Electric | PLC series TSX |

|

| PLC series Twido |

|

|

| PLC series Zelio |

|

|

|

Protective Relays series SEPAM |

|

|

| Siei |

Inverters series ARTDriveG |

|

| Siel |

Inverter series Greenpoint |

|

|

Inverter series Safepower- Evo |

|

|

|

Inverter series Soleil |

|

|

| Siemens |

Inverters Simovert |

|

|

PLC series S5 |

|

|

|

PLC series S7-1200 |

|

|

|

PLC series S7-1500 |

|

|

|

PLC series S7-200 |

|

|

|

PLC series S7-300/400 |

|

|

|

PXC36 |

|

|

| Socomec |

Energy meters series DIRIS |

|

|

Insulation indicators series ISOM |

|

|

| Tecnologic |

Front panel instruments |

|

| Telemecanique |

PLC series TSX |

|

| Tutondo |

Tutondo MR6005 |

|

|

Tutondo MR9005 |

|

|

|

Unitronics |

PLC series Jazz Micro |

|

| PLC series M90/M91 OPLC |

|

|

| PLC series Vision120 |

|

|

| PLC series Vision2XX |

|

|

| Vipa | PLC series System |

|

| Wago | Modules I/O series 750 |

|

| Watlow | Front panel instruments |

|

Devices Support

Application Builder is a powerful tool that allows the automatic creation of SCADA applications, resulting in a dramatic reduction in development timescales. You can create a software application by simply taking up from a library and putting together objects relating to various automation instruments such as PID controllers, indicators, I/O modules, etc.

In addition to tags and protocols, objects may include supervisory and configuration templates (front panel, trends, etc.) and a list of events and alarms with their management procedures. Objects can be built using the Multi-language option to allow the automatic creation of Multi-language applications.

The Winlog Pro library can be enriched with other objects that can be built and included by the user or developed by Sielco Sistemi on custom request. Here below are listed all objects included in the basic Winlog Pro package:

| Manufacturer | Device |

| ABB | ABB ACS 600 |

| ASCON | Ascon X3 Ascon M1 Ascon M3 Ascon M4 Ascon D1 Ascon D2 Ascon D3 Ascon D7 Ascon D8 Ascon D9 Ascon Kube KM3 Ascon Kube KM5 Ascon M5 |

| ASTEEL | ASTEEL WIMT2A |

| AVE | AVE_ABDI AVE_ABR AVE_ABRT AVE_ABT |

| CR MAGNETICS | DataStream_CRD5110 DataStream_CRD5150 DataStream_CRD517 |

| DIGITEK | Digitek MP10 |

| DYNISCO | Dynisco ATC 770 Dynisco UPR 700 |

| EROELECTRONIC | EROelectronic LFS EROelectronic PKC EROelectronic MCC EROelectronic TFS EROelectronic TKS EROelectronic LHL EROelectronic LHI EROelectronic MKS |

| EUROTHERM | Eurotherm 2208e Eurotherm 2216e Eurotherm 584SV Eurotherm 590DC Eurotherm 590+ Eurotherm 620L Eurotherm 690+ Eurotherm 2704 |

| GEFRAN | Gefran 800 Gefran 1600 Gefran 1800 |

| JUMO | Jumo dTRON 081 E1 Jumo Imago 500 Jumo dTRON 081 I1 Jumo dTRON 081 |

| REEL | Reel LZXA08B |

| SHINKO | Shinko ACS13A Shinko DCL33A Shinko JCD33A Shinko JCR33A Shinko JCS33A |

| SIELCO SISTEMI | IOLOG SS-3014 IOLOG SS-3015-I IOLOG SS-3015-V IOLOG SS-3016-mV IOLOG SS-3016-TC IOLOG SS-3017-I IOLOG SS-3017-V IOLOG SS-3018-mV IOLOG SS-3018-TC IOLOG SS-3024 IOLOG SS-3130 IOLOG SS-3148 IOLOG SS-3188 IOLOG SS-8014 IOLOG SS-8015 IOLOG SS-8016 IOLOG SS-8017-I IOLOG SS-8017-V IOLOG SS-8018 IOLOG SS-8024 IOLOG SS-8130 IOLOG SS-8148 IOLOG SS-8188 IOLOG SS-10014 IOLOG SS-10015 IOLOG SS-10016 IOLOG SS-10017-I IOLOG SS-10017-V IOLOG SS-10018 IOLOG SS-10130 IOLOG SS-10148 IOLOG SS-10188 |

| SOCOMEC | Socomec DIRIS A10 Socomec DIRIS A20 Socomec DIRIS A40 Socomec DIRIS A60 |

| TECNOLOGIC | Tecnologic TDA-04 Tecnologic TDA-08 Tecnologic TLK31 Tecnologic TLK31-T Tecnologic TLK32 Tecnologic TLK33 Tecnologic TLK35 Tecnologic TLK43 Tecnologic TLK43-Z Tecnologic TLK72 Tecnologic TLV31 Tecnologic TLV35 Tecnologic TLY26 Tecnologic TLK32-T Tecnologic TLK35-T |

| TOHO | Toho TTM-004S |