Predictive Maintenance Using Delphin Data Center

Maintenance systems for the condition monitoring of plant and machinery are already well established with the trend now increasingly moving towards predictive maintenance. This trend is becoming more and more important in the context of smart industry, i.e. continuous condition monitoring through to the detailed analysis of correlations and patterns using special algorithms.

Maintenance systems for the condition monitoring of plant and machinery are already well established with the trend now increasingly moving towards predictive maintenance. This trend is becoming more and more important in the context of smart industry, i.e. continuous condition monitoring through to the detailed analysis of correlations and patterns using special algorithms.

Predictive maintenance aims to proactively maintain machines and systems and thus keep downtimes to the minimum. To achieve this and go beyond the reactive and preventive maintenance of standard condition monitoring requires the efficient processing of large volumes of heterogeneous data.

Diverse demands

In practice, the task is to centrally record, store, process and analyse a wide range of different process and machine information. This places major demands on measurement technology, e.g. for a wide range of universal analogue and digital inputs and outputs, serial interfaces and protocols, as well as advanced capabilities for storing and processing measurement data. Highly heterogeneous measurement data makes it much more difficult to analyse and evaluate as well as calculate error occurrence probabilities. An intelligent measurement system is therefore required, which is able to process measurement data at the point of acquisition, homogenising it for subsequent analysis and evaluation.

This is where current-day measurement technology is bridging the gap between Industry 4.0 and big data. Such technology is key to implementing efficient and effective predictive maintenance. Delphin provides support to enable you to easily implement this key technology for your maintenance strategies.

You can achieve the above with the Delphin Data Center as a centralised measurement data management system, and ProfiMessage D as a modular measurement, control and monitoring device.

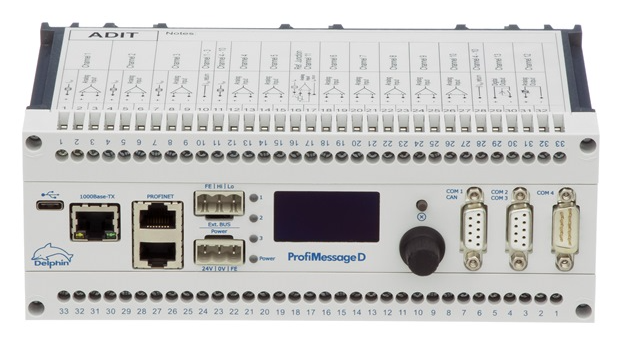

ProfiMessage D was specially designed for this area of application. The device can be adapted to individual requirements via its master/slave device capability and its modular design with a diversity of I/O modules. ProfiMessage D’s range of interfaces and protocols also provides many options for communications and data sharing with third-party hardware such as PLCs, frequency converters and smart third-party equipment.

The Delphin Data Center can stream this data regardless of source and location enabling measurement and process data from any source to be merged, synchronised, intelligently processed and made available for analysis. Using the Delphin Data Center also eliminates the need for manual and any extensive programming effort required for implementing cross-system data processing.

The Delphin Data Center and the ProfiMessage D device provide solutions tailored to your individual needs for implementing and utilising predictive maintenance strategies.

For more information, please contact us, or visit the product pages for Delphin Data Center and ProfiMessage D.